Maintainability Analysis

Background:

1. Calculate Metrics Based on Repair Time Data

Given time-to-repair data, this tool calculates the mean, median, and maximum corrective time-to-repair, assuming a lognormal time-to-repair distribution.

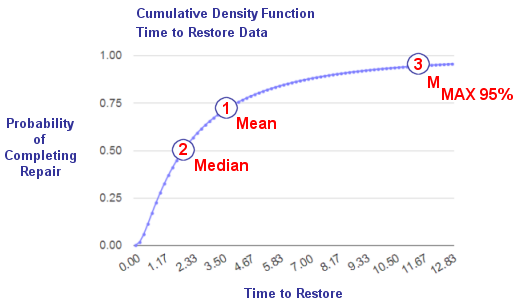

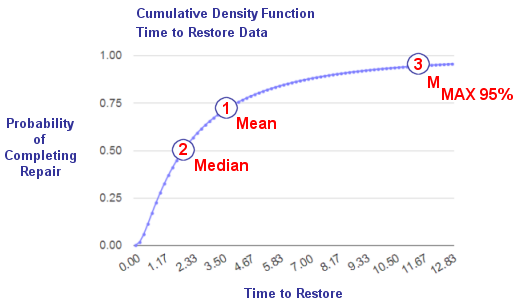

Some of the commonly used maintainability engineering terms are shown on maintainability function, M(t), illustrated below. The M(t) curve is a cumulative density function that provides an estimate of the probability of completing an arbitrary system repair action in a given amount of time. Points 1, 2, and 3 shown in the figure identify the mean, median, and maximum corrective time-to-repair, respectively. Given time-to-repair data, this tool calculates the time values associated with these points.

For further details, see this blog post and reference 1 below. For a quick example, skip inputs one and two and select the test set in the Options area below.

2. Estimate MMax Based on a Known MTTR

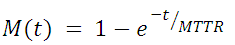

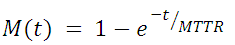

In the absence having actual data for computing the standard deviations of repair times, the exponential distribution is often used as an approximation of the lognormal distributing for estimating the

maximum corrective maintenance time for system repair actions. Using this approximation, say to estimate the maximum repair time for 95% of all repair actions, requires only a known mean time to repair (MTTR).

This approximation is given by the following equation:

where:

M(t) = probability of repair in a specified time t

MTTR = mean time to repair

To make this calculation, ignore input box 1 input, set input 2 and enter an MTTR in the Options area. Plots are also an option.

Calculation Inputs:

Featured Reference:

Maintainability: A Key to Effective Serviceability and Maintenance Management

Maintainability: A Key to Effective Serviceability and Maintenance Management

Toolkit Home

Comments/Questions:

reliabilityanalytics.com

References:

- MIL-HDBK-338, Electronic Reliability Design Handbook.

- Bazovsky, Igor, Reliability Theory and Practice.

- O'Connor, Patrick, D. T., Practical Reliability Engineering.

- DoD Guide for Achieving Reliability, Availability and Maintainability .

- MIL-HDBK-470A, Designing and Developing Maintainable Products and Systems

- MIL-HDBK-472, Maintainability Prediction

- MIL-HDBK-472, Notice 1, Maintainability Prediction

- MIL-HDBK-338B, Exponential Approximation to the Maintainability Function.

- MIL-HDBK-338, Exponential Approximation to the Maintainability Function.

- Birolini, Alessandro, Reliability Engineering: Theory and Practice.

- Ebeling, Charles E. An Introduction to Reliability and Maintainability Engineering.

- Blanchard, Benjamin S.; Verma, Dinesh C.; Peterson, Elmer L. An Introduction to Reliability and Maintainability Engineering.

- Dhillon, B.S. Engineering Maintainability: How to Design for Reliability and Easy Maintenance.

Copyright © 2010 - 2023 Reliability Analytics Corporation

Privacy Policy

All content and materials on this site are provided "as is" Reliability Analytics makes no warranty, express or implied, including the warranties of merchantability and fitness for a

particular purpose; nor assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed;

nor represents that its use would not infringe privately owned rights.