1. Unit failure/repair characteristics

(edit/copy/paste example input to make new entries, or use the Excel template above).

Column 1 entry must be unique, otherwise the failure and restore characteristics for the last entry with the same key (serial number) will be used.

Columns 1, 2 and 3 are required. These are a serial number (i.e., any unique key/name), failure characteristic and restoration characteristic, respectively.

Column 4 is item description and column 5 part number. Both of these are optional, but may be useful if exporting results to Excel and performing post simulation analysis (e.g., how many failures for a given part number).

Failure characteristic 800,200,n means a normally distributed life of 800 hours, with a standard deviation of 200 hours.

Restoration characteristic 168,48,n means a normally distributed restore time of 168 hours, with a standard deviation of 48 hours.

Failure characteristic 20000,e means an MTBF of 20,000 hours, with an exponential failure distribution.

Repair time for sn6 is exponentially distributed with a mean of 48.

Failure characteristic 1000,3.5,w means a Weibull characteristic life of 1000 hours, with a Weibull shape parameter of 3.5.

Single number entries mean exact times. snA "fails" every 2,190 hours (exactly) and is restored in exactly 1 hour.

unique SN | failure characteristic | repair characteristic | desc. (optional) | part no. (optional)

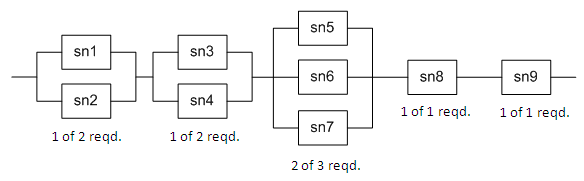

2. Failure combinations that result in a critical failure

(enter one combination per line, with each unit serial number separated by a comma).

This input is optional. It can be used to define a "watch list" for various combinations of failure events. Only SNs previously defined in box #1 above are meaningful input.

After each simulated failure event, each set of items (one set per line below)

is compared to the current list of items in a failed state. If the set of items listed on a line below is a subset of the current set of failed items, then a "critical failure" is tallied.

This tool (option 1d) may be helpful to enumerate all possible states for a given list of serial numbers, which can be exported to Excel, specific combinations selected, and pasted into the box below.

one set per line

3. Regularly scheduled preventive maintenance (PM) interval

(enter one unique serial number per line, followed by a comma and the scheduled maintenance interval (hours). If restoration is only performed at scheduled intervals, add the word "delayed" in the optional third field.).

This input is optional. It can be used to define a regularly scheduled maintenance interval when a specific serial numbered item is restored to "as good as new." For the example input shown below, all units are restored to "as good as new" at the time interval indicated; however, if either of the bearings fail (sn8 or sn9), restoration begins immediately, taking the time defined in box #1 above. If either of the control units fail (sn3 or sn4), restoration is delayed until the next regularly scheduled maintenance, which occurs every 4,000 hours. Only SNs previously defined in box #1 above are meaningful input.

unique SN, scheduled PM interval, delay flag (optional)